Researchers have made a significant breakthrough in microscopic 3D printing by integrating metalenses into two-photon lithography systems, dramatically enhancing precision and speed. This innovation leverages the unique ability of metalenses to manipulate light at the nanoscale, opening new possibilities in microfabrication and nanotechnology.

What Are Metalenses?

Metalenses are ultra-thin, engineered optical components that can bend and focus light in ways conventional lenses cannot. Unlike traditional glass lenses, which rely on curved surfaces, metalenses use nanoscale structures to control the phase, amplitude, and polarization of light. This allows for unprecedented control over light propagation, enabling sharper focus and higher-resolution imaging at microscopic scales.

Advancing Two-Photon Lithography

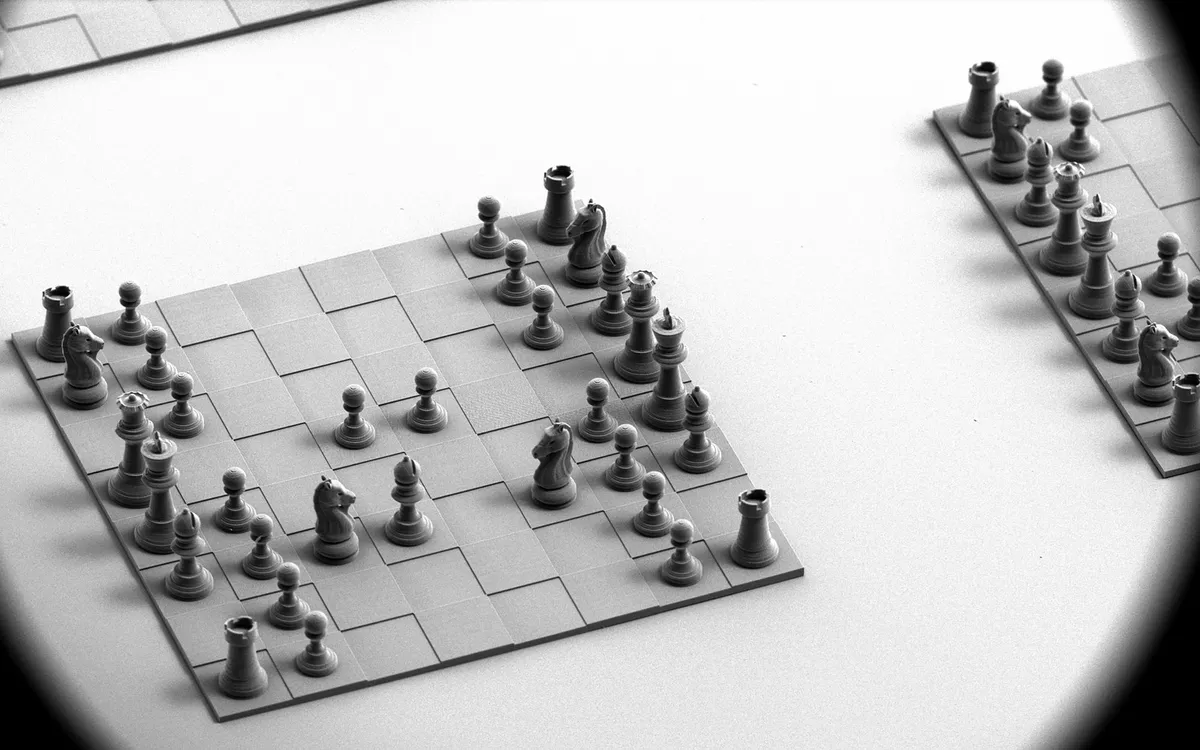

Two-photon lithography is a 3D printing technique that uses laser pulses to solidify photosensitive materials with extreme precision, often at the nanometer scale. The addition of metalenses has several key benefits:

- Improved Focus Precision: Metalenses can tightly focus laser beams, reducing aberrations and increasing resolution for complex 3D structures.

- Faster Fabrication: By efficiently directing light, metalenses allow for quicker curing of materials, accelerating the printing process.

- Enhanced 3D Complexity: The technology enables the creation of intricate, previously unattainable geometries, from micro-optical devices to biomedical scaffolds.

Implications for Science and Industry

The combination of metalenses with two-photon lithography has far-reaching applications:

- Biomedical Engineering: High-precision scaffolds for tissue engineering and drug delivery systems can be fabricated with improved accuracy.

- Microelectronics: Advanced microchips and photonic circuits benefit from nanoscale patterning enabled by the enhanced laser focus.

- Optics and Nanotechnology: Metalens-assisted 3D printing allows for the production of custom optical devices with complex internal structures.

The Physics Behind the Breakthrough

The innovation hinges on light-warping physics. Metalenses manipulate the phase of incoming light waves, allowing lasers to be focused more tightly than conventional optics permit. This precise control ensures that only the targeted regions of the photosensitive material are cured, reducing errors and material waste.

Researchers note that this approach also reduces the reliance on bulky optical setups, making the technology more compact and scalable for industrial use.

Future Prospects

The integration of metalenses into two-photon lithography could redefine standards for microscopic 3D printing, enabling faster, more accurate, and more complex fabrication. As the technology matures, it may unlock new possibilities in medicine, electronics, and materials science, pushing the boundaries of what can be manufactured at the micro- and nanoscale.

In essence, metalenses are not just enhancing 3D printing—they are reshaping the very way light can be used to create structures at microscopic scales.

Leave a Reply