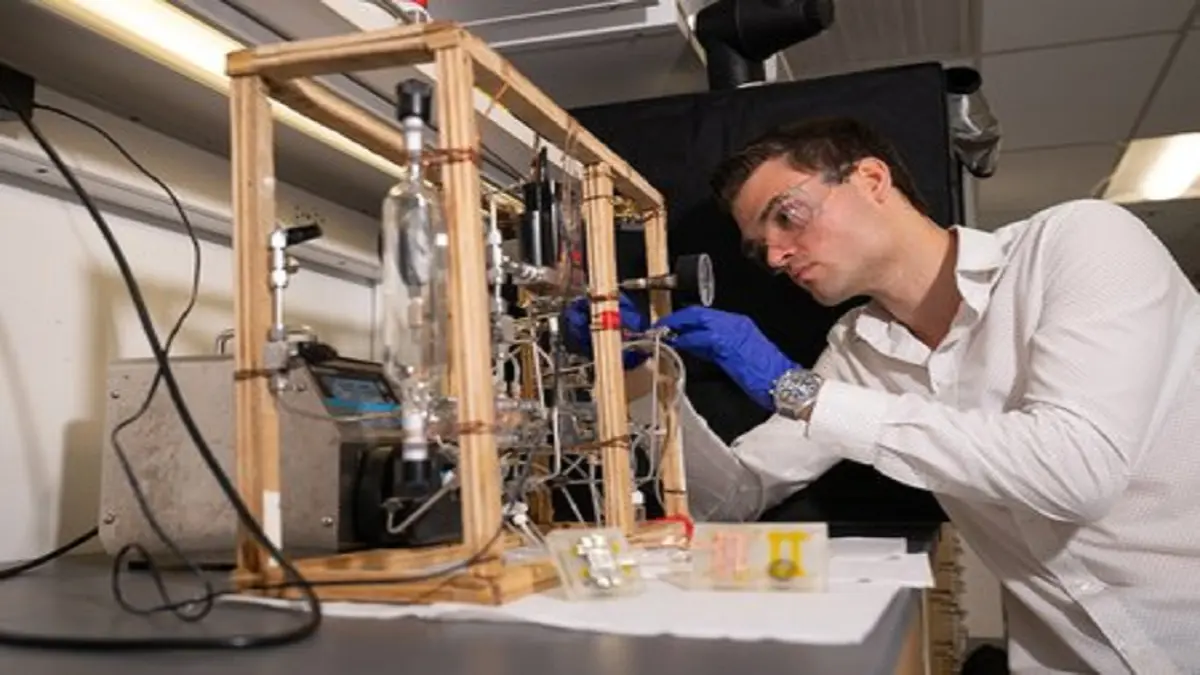

A team of researchers at the University of Copenhagen has unveiled a groundbreaking discovery that could help fight both plastic pollution and climate change at once. By converting discarded PET plastic, commonly used in bottles and packaging, into a new material named BAETA, scientists have created an efficient tool for capturing carbon dioxide emissions.

From Plastic Waste to Climate Solution

PET plastics are one of the most persistent forms of waste, often ending up in oceans and landfills where they break down into harmful microplastics. Instead of letting this waste accumulate, the researchers found a way to transform it into a resource that can actively remove greenhouse gases from the atmosphere.

The result is BAETA—a fine, powdery substance with a chemically engineered surface designed to bind CO₂ molecules. What makes BAETA especially promising is its ability to release captured CO₂ when heated, allowing for the gas to be stored or reused while the material itself is regenerated for multiple cycles of use.

High Efficiency and Industrial Potential

One of BAETA’s standout features is its durability under industrial conditions. Unlike some carbon-capturing technologies that require strict environmental controls, BAETA works effectively across a wide temperature range—from normal room conditions up to around 150 °C. This flexibility makes it ideal for installation in chimneys and exhaust systems where gases are released at varying temperatures.

The process for producing BAETA is also remarkably energy-efficient. It can be synthesized at room temperature, which means scaling up production for industrial applications would not require excessive energy input.

Tackling Two Global Crises at Once

The implications of this research are enormous. On one hand, it creates a practical pathway to reduce industrial CO₂ emissions at the source. On the other, it provides a valuable use for plastic waste, helping address the global crisis of pollution that threatens ecosystems worldwide.

By turning a pollutant into a climate solution, the University of Copenhagen team has opened the door to a new kind of circular economy—one in which yesterday’s waste becomes tomorrow’s resource.

The Road Ahead

The next step is scaling production of BAETA to industrial levels, with the goal of manufacturing it in ton-scale quantities. If successful, this material could be deployed globally, capturing carbon from power plants, factories, and other high-emission sources.

The researchers believe this discovery could even create new economic incentives for cleaning up plastic waste in oceans and landfills, since that material could be transformed into something of real environmental and industrial value.

Leave a Reply